The more likely that an explosive mixture and an inflammable spark “meet”, the more likely it is that an explosion will occur. The more likely it is that an explosive mixture will occur, e.g. our flour dust or the petrol cloud, the safer the installed or carried equipment technology should be!

That's why it makes sense to divide areas at risk of explosion up by the probability of an explosive mixture occurring:

| Zone 20 | is extremely dangerous! This is a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently! |

| Zone 21 | is dangerous! This is a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally! |

| Zone 22 | is not very dangerous. This is a place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only! |

| Even safer Area | is non-hazardous. An explosive dust cloud NEVER occurs. This type of area is known as a “safe area” or a “zone-free area”. |

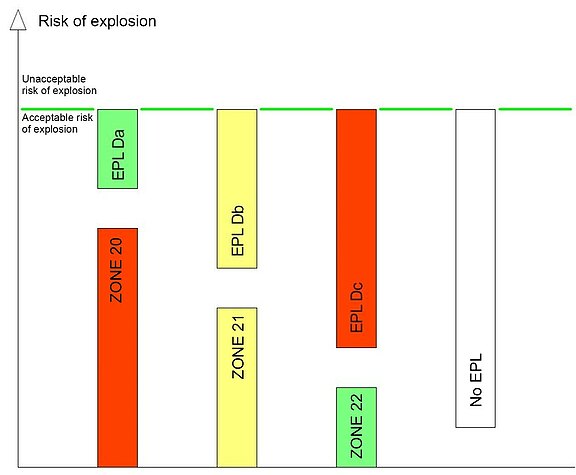

Continuously occurring Ex-atmospheres (zone 20) require extremely safe equipment.

Occasionally occurring Ex-atmospheres (zone 21) require very safe equipment.

Ex-atmospheres that only persist for a short period (zone 22) require safe equipment.

The equipment technology does not matter in an Ex-atmosphere that never occurs.

Extremely safe equipment to fight against zone 20

Very safe equipment against zone 21

Safe equipment is sufficient in the fight against zone 22

And any equipment is OK if we are free of zones.

| Clearly expressed | The Europeans say

| The international standard setters say

|

|

| Equipment category in accordance with Directive 2014/34/EU | Equipment Protection Level (EPL) in accordance with IEC 60079-0 |

Zone 20 requires | .. extremely safe equipment | D1 | Da |

Zone 21 requires | .. very safe equipment | D2 | Db |

Zone 22 requires | .. safe equipment | D3 | Dc |

Zone free requires | ..whatever | - | - |

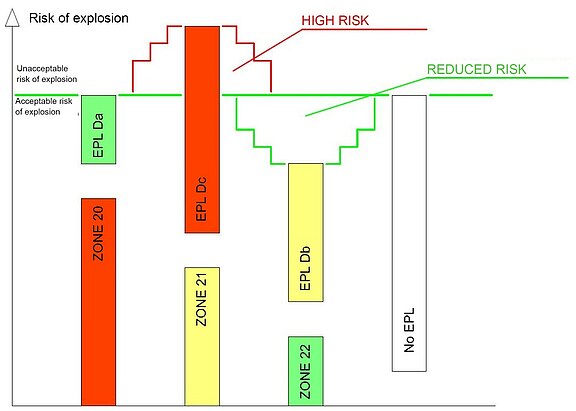

The equipment technology must NEVER be weaker than required by the zone. “Better than you need” is always OK.

Only use equipment with category Da in zone 20. Equipment in categories Da and Db can be used in zone 21 and equipment in categories Da, Db or Dc can be installed in zone 22.

Dust groups versus equipment groups

Inflammmable dusts are divided into dust groups.

GROUP | DUST | EXAMPLE |

IIIA | Combustible lint | Cotton, filter materials |

IIIB | Non-conductive dust | Sugar dust, flour |

IIIC | Conductive dust | Aluminium dust |

Dust group | Equipment group |

IIIA | IIIA or IIIB or IIIC |

IIIB | IIIB or IIIC |

IIIC | IIIC |

Temperatures to be considered

Ambient temperature

A permissible ambient temperature is always specified for a piece of Ex equipment if the piece of equipment is permitted to be operated beyond the ATEX standard temperature range (-20°C to +40°C). Some of our cameras are safe from -60°C to +60°C for example. This temperature range is the “approved temperature range for the equipment”. Ensure that these specifications meet your system’s requirements.

Ignition temperature

The ignition temperature of a dust cloud is the lowest temperature on a heated surface at which an explosion occurs. The maximum surface temperature for pieces of equipment must be lower than the dust cloud’s ignition temperature.

Smouldering temperature

The smouldering temperature is generally lower than the ignition temperature and the thickness of the dust layer is also decisive with regard to smouldering. The thicker the dust layer, the more energy it has and therefore, the more hazardous it is. Our standardising organisations have analysed layer thicknesses of 5mm, thicker layers were not considered. This means: try to avoid layer thicknesses of more than 5 mm. If you cannot manage this for structural reasons, these deposits must be evaluated separately in your explosion protection document.

Maximum surface temperature for equipment

The maximum surface temperature for a piece of equipment must be lower than 2/3 of the lowest ignition temperature.

The maximum surface temperature must be 75K below the dust layer’s smouldering temperature.

The equipment manufacturer’s specifications for the maximum surface temperature relate to equipment operation at the maximum permissible ambient temperature.

The equipment manufacturer’s specifications for the maximum surface temperature are not provided in temperature classes, but are rather specified as concrete values in degrees Celsius.

What has to be done?

Avoid inflammable dusts in your system wherever possible. Use dust filter systems wherever you can. Sometimes, dust cannot be avoided, but you can remove it from wherever it has accu-mulated. Therefore, removing inflammable dust on a regular basis is a significant safety-related preventive measure when it comes to explosion protection. Use suitable extraction systems and ensure that the extraction system is suitable for your dusts and your Ex zone.

Air purge systems

Air purge systems are not so popular in dust Ex zones. The reason for this is obvious: inflammable dusts are swirled up by air purge systems and therefore “turned into” an explosive dust cloud. This is potentially so dangerous that project planning for air purge systems has to be particularly good.

They only make functional sense if the dust is problematic “in a specific location”. For example, on a camera lens, on a sight glass or a temperature hotspot. The motto here is: “There shouldn’t be any dust here, it should settle somewhere else.”

The following MUST be considered for air purge systems:

Air purge systems must be considered when classifying the zones!

For example, your zone 22 can quickly become zone 21 if you purge the air “every half hour“.

Equipment in the air purge systems, e.g. solenoid valves, must correspond to the zone classification!

For example, use a solenoid valve that is approved for zone 21 in zone 21.

Design the air purge device to be fail-safe! Air purging must not take place continuously, in order to prevent dust being swirled up continuously. This can be ensured using two solenoid valves that are switched in sequence, for example, or by a combination of manual and automatic valves.

If possible, combine your air purge system with a suitable local extraction system so that your dust is collected immediately and cannot settle again. For more information regarding air purge systems for explosion-protected camera systems, see our air.Blade.

If you have exhausted all opportunities for avoiding an explosive dust atmosphere, the next step is as follows: Avoid sources of ignition!

Avoid sources of ignition

Does the equipment have to be installed in the Ex area? Avoided Ex equipment is safe Ex equipment! Check whether the task that the equip-ment must fulfil REALLY requires installation in the Ex zone! This is often the case but often not! Avoid having to install equipment in the Ex area wherever possible!

Selecting the correct equipment protection level

Define the required equipment protection level: Only use equipment with category Da in zone 20. Da and Db can be used in zone 21. And Da, Db and DC can be installed in zone 22.

Selecting the correct equipment group

Define the required equipment group: Only use IIIC equipment in dust group IIIC. IIIB and IIIC equipment is suitable for dust group IIIB. And IIIA, IIIB and IIIC equipment may be used in dust group IIIA.

Observe the temperatures

Define the ambient temperature range for your equipment. How hot does it get in your system? Can the equipment cope with that? Is the equipment still safe when it is that hot? How cold does it get in your system? Can the equipment cope with that? Is the equipment still safe when it is that cold?

What is the maximum surface temperature that the equipment may have? Determine the maximum surface temperature that equipment in your system may have, as described in section 4. If the temperature specifications for the maximum surface temperature are listed on the equipment’s type plate, everything is OK. If not, find a piece of equipment that does not get too hot.

Dust and/or gas?

What actually happens if I have an atmosphere that is at risk of dust and gas explosion at the same time? Many customers think this isn’t a problem because both the marking for dust and the marking for gas are on the type plate. But this is a misconception. The equipment is approved for dust and gas but simultaneous occurrence is a special situa-tion that has not been simulated and that is not covered in the standard. So it is there-fore possible that, if a gas explosion occurs in a pressure-resistant housing, hot ignition gas can ignite an exterior dust atmosphere. The following therefore applies:

Gas Ex equipment in a gas Ex atmosphere? Yes!

Dust Ex equipment in a dust Ex atmosphere? Yes!

Dust and gas Ex equipment in a simultaneous dust and gas Ex atmosphere: No!

Closing remarks

We hope that we have succeeded in explaining the risk of dust explosion and dust explosion protection simply and basically. Much was omitted, such as topics regarding the lower or upper explosion limit, and we only scratched the surface of other topics such as the ambient temperature range. It is also clear that cables and lines, fire-retarding sealings, etc. are also part of clean project planning for Ex systems, but these were not mentioned even once in this report. In short: reading this brochure will not make you an Ex expert. Despite that, we hope that you now have a basic understanding of why the regulations are the way they are.

If you have any comments or questions, no matter what they are, feel free to contact us Sales Team