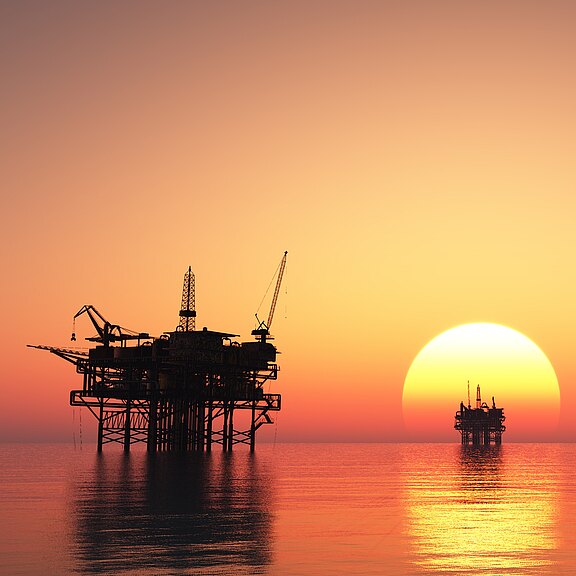

Explosion Proof Cameras and Lightning for Oil and Gas

Reliable Safety in Onshore and Offshore Operations

Explosion proof cameras and hazardous area lighting systems from SAMCON are essential for the oil and gas industry. They ensure safe and effective monitoring and documentation across upstream, midstream, and downstream operations, covering offshore drilling rigs, wellheads, tank farms, refineries and long-distance pipelines. Our ATEX certified cameras, IECEx CCTV systems and Class I Division 1 or Division 2 (in progress) cameras provide reliable surveillance in hazardous areas and help protect personnel, assets and the environment. With stainless steel housings designed for Ex environments, the devices withstand vibrations, saltwater spray, extreme heat, freezing cold and mechanical stress without ever posing an ignition risk. Particularly effective is the use of remote hazardous area CCTV monitoring for continuous safety assurance in both onshore and offshore facilities.

Applications

SAMCON explosion-proof cameras and lightings play a critical role in different parts of oil and gas operations. They are used for real-time surveillance of drilling platforms, refineries, LNG plants and storage tanks in order to detect incidents at the earliest stage and initiate immediate countermeasures. Pipeline monitoring with explosion proof cameras is essential to detect leaks, protect workers and avoid environmental damage. Wellheads in Ex zones can be supervised to improve operational safety. The same applies to tank farms, where hazardous area monitoring prevents accidents and ensures compliance.

In addition to surveillance, explosion proof IP cameras allow remote inspection of hazardous or difficult-to-access areas such as compressor stations. This minimizes manual interventions, reduces downtime and lowers maintenance costs while enabling continuous visual diagnostics. Process monitoring with Ex cameras ensures operational efficiency by transmitting real-time data such as pressure, temperature and flow rates directly to the control system. Thermography is particularly valuable in LNG plants, where precise temperature monitoring can prevent critical incidents.

Explosion proof CCTV systems also support documentation and reporting. Video recordings of operations and incidents can be stored for later analysis or compliance reporting. The integration of hazardous area cameras into process control systems ensures continuous and tamper-proof documentation, creating a reliable basis for audits and regulatory requirements.

SAMCON provides camera and lighting solutions that meet all global certification standards, including ATEX Zones 1, 2, 21 and 22 in Europe, IECEx certifications in the Middle East and Asia, Class I Division 1 and Division 2 in North America (in progress) as well as INMETRO, PESO, EAC-Ex, UKEX and MASC approvals. The rugged stainless steel enclosures offer corrosion resistance against saltwater, chemicals and harsh offshore conditions. With a wide operating temperature range from minus 60 to plus 130 degrees Celsius and optional active cooling or heating, the systems are designed for extreme environments. The portfolio covers both standalone explosion proof cameras and complex CCTV installations with audio communication and integration into process control systems. All products are engineered and manufactured in Germany and tested by leading notified bodies such as DEKRA and TÜV.

Why SAMCON?

SAMCON solutions support oil and gas operators in reducing risks, ensuring compliance with global explosion protection standards and maintaining safe and efficient operations across the entire energy value chain.

Our products are always just tools of our project planning. None of our products are the result of a project without a requirement! We see ourselves as a solution provider.

Check us out! Get in touch with us or simply contact us by e-mail!